絞り込み

Pumps for Specific Applications

Chemical Models

-

TMH models

- Pumps for Specific ApplicationsChemical Models

for the chemical industry

for the chemical industry

TMHM-21N, TMHM-316M (100V, air motor compatible)

●Compact, lightweight and easy to operate.

●Corrosion resistant design.

· TMHM-21N, suitable for transfer solutions of acids and alkalis

· TMHM-316M made of SUS316 for the solvent

●It can also be used for pail cans, plastic cans, and cubitainers (diameter φ31).TMH-55N2 (100V compatible)

●A high lift is achieved by adopting a high-efficiency impeller.

●Weight is reduced by using a compact motor.TMH-108 (100V, air motor, explosion-proof electric motor [100V] compatible)

●The continuous-rated, fully-enclosed fan-cooled motor is covered with integrally molded resin to improve the motor's corrosion resistance and electrical resistance.

●As a motor compatible with explosion-proof environments, we have prepared an explosion-proof motor (d2G3) specification that has passed the type test specified by the Minister of Health, Labor and Welfare.TMH-105 (100V, air motor compatible)

●A high lift (12m) and a large capacity (105ℓ/min) are possible by adopting a high-efficiency impeller.

●Surplus operation due to increased output.

●Even though it uses a large electric motor, the weight is reduced.TMH-107D (SUS) (100V, air motor, explosion-proof electric motor [100V] compatible)

●Corrosion resistant design.

● Made of SUS304, it has excellent chemical resistance. (Designed to be compatible with organic solvents)

●Non-seal structure without liquid leakage. -

TMTX models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Since the entire pump is covered with plastic, there is almost no rust and the appearance is not spoiled.

●Long-term continuous operation is possible due to planetary gear two-stage reduction.

●Aluminum material is used in combination to reduce weight.

● Quality has been improved by improving the ratchet mechanism. -

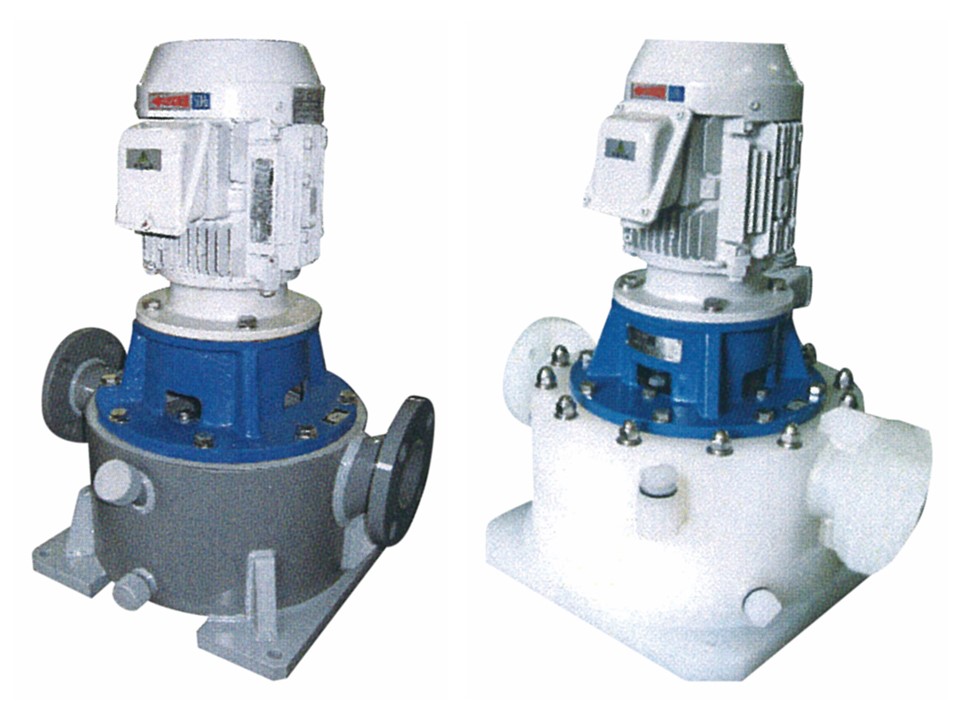

TMOK-S models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●The adoption of CSS (centrifugal shaft seal device) ensures that the seal is non-contact and non-sliding during operation.

There is no wear of seals due to slurry or heat generation due to dry operation.

●It is also possible to manufacture PTFE or UPE depending on the liquid used. -

TMOK-V models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Dry operation is OK due to the non-seal structure.

●Few consumable parts. -

TN models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Magnetic pump for a wide range of chemicals.

●Faithful to the basics, highly reliable and long-life design.

● Abundant series configuration from 6W to 250W. -

TM models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●As a medium-capacity chemical magnet pump, materials and structures for a wide range of chemical liquids are available.

●There is no liquid leakage due to the magnet drive structure.

●It supports a wide range of chemicals by selecting the wetted part material.

●Casting (FCD) models with an exterior cover are ideal for high temperature and high pressure applications.

● All standard motors are totally enclosed fan-cooled outdoor type.

●It has a long service life by adopting a structure that is resistant to idling.

FAQs

Provides help information on how to use each product and when you have problems.