絞り込み

for the chemical industry

-

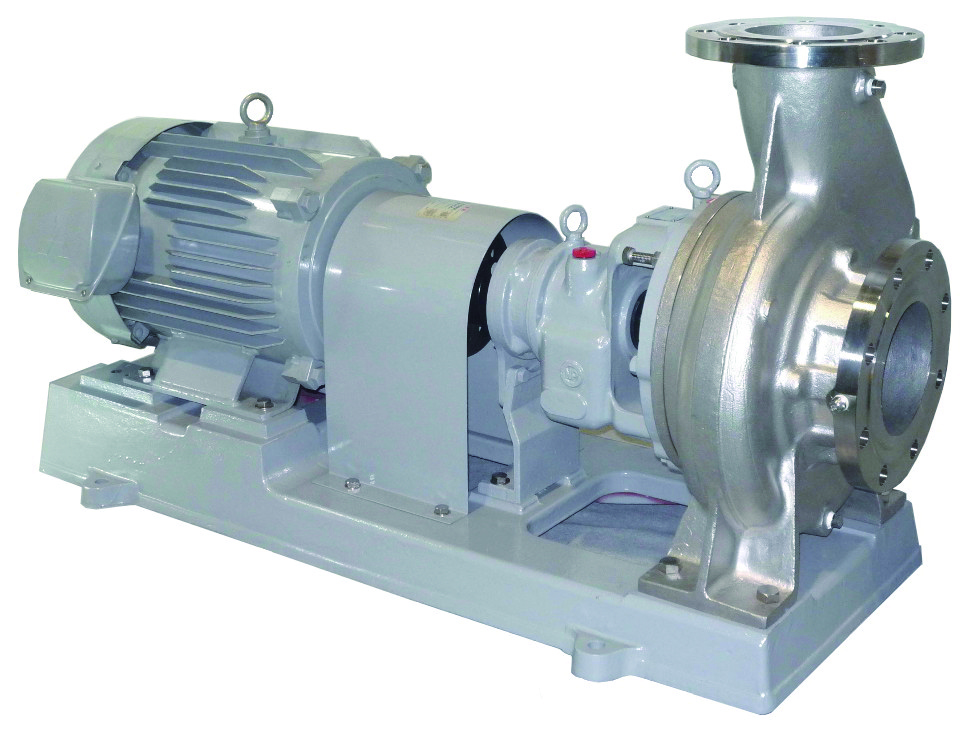

TUFSM/TJSM (2P) mechanical seal SCS14 models

- On-Land Pumps (Stainless Steel)Direct-Coupled/Non-Self-Priming Models

for high pressure

for high pressure for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

(TUFS type)

●Rational design and thorough quality control ensure high reliability, durability, and interchangeability of parts.

●High efficiency reduces initial and running costs.

●The pump is designed to be small by using a 2-pole motor for high head.

●Gland packing is standard for the shaft seal.

It is also possible to manufacture a water-cooled system.

(TJS type)

● High-efficiency pumps have been made into a series with two poles, allowing selection according to the application.

●Maintenance is easy with the adoption of the B.P.O (back pull-out) method that can be disassembled without removing the piping.

● The shape of the center top and foot support is advantageous for piping load.

● Abundant variations can meet all kinds of needs. -

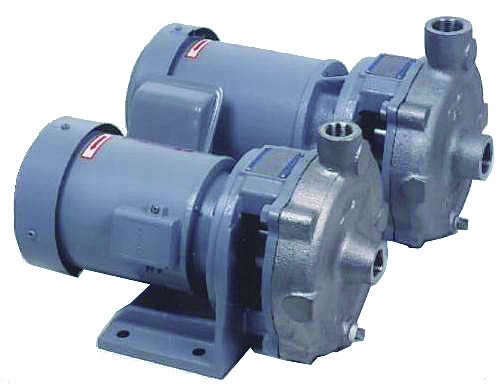

TSLP2 (2P) mechanical seal models

- On-Land Pumps (Stainless Steel)Close-Coupled/Non-Self-Priming Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Since it is a precision stainless steel casting, it is strong, resistant to distortion, and has a long service life.

● High permissible pushing pressure allows safe operation.

●Since it uses a highly durable mechanical seal, there is no water leakage and maintenance is easy.

●Wetted parts are made of stainless steel, preventing rusty water.

●Compact and lightweight, in-line type that can be installed in the middle of piping, so it can be installed in a small space. -

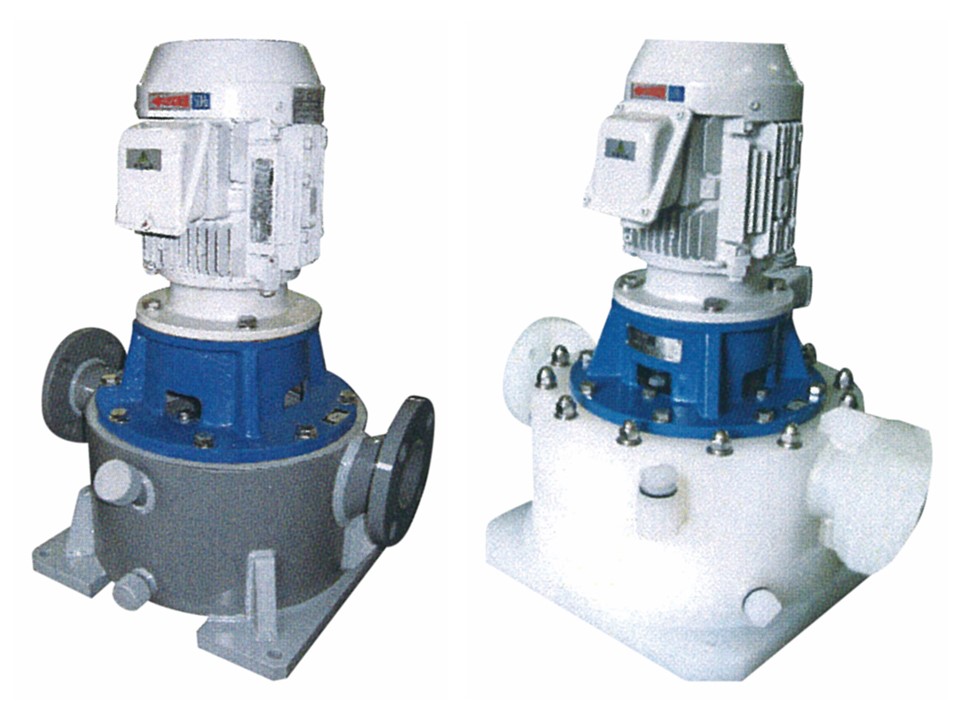

TFSD (2P) mechanical seal models

- On-Land Pumps (Stainless Steel)Close-Coupled/Non-Self-Priming Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

● Excellent durability due to the adoption of stainless steel casting.

● A highly reliable mechanical seal (SiC) is used for the shaft seal.

●The impeller adopts a durable semi-open type, and can pass some solid objects.

●Simple and compact integrated motor shaft structure eliminates the need for centering.

●Because of the center top structure, the discharge direction can be changed freely regardless of the mounting direction.

● Quiet driving sound. -

CS-N models (non-automatic)

- Submersible PumpsPlastic/stainless steel models

for fishing

for fishing for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

● High-grade stainless steel SUS316 and SCS14 are used for all wetted parts. Resistant to acids, alkalis and salts.

● A double mechanical seal with excellent corrosion resistance and durability is used for the shaft seal.

●Equipped with an automatic burnout prevention device in the motor. (7.5kW or less) -

TMH models

- Pumps for Specific ApplicationsChemical Models

for the chemical industry

for the chemical industry

TMHM-21N, TMHM-316M (100V, air motor compatible)

●Compact, lightweight and easy to operate.

●Corrosion resistant design.

· TMHM-21N, suitable for transfer solutions of acids and alkalis

· TMHM-316M made of SUS316 for the solvent

●It can also be used for pail cans, plastic cans, and cubitainers (diameter φ31).TMH-55N2 (100V compatible)

●A high lift is achieved by adopting a high-efficiency impeller.

●Weight is reduced by using a compact motor.TMH-108 (100V, air motor, explosion-proof electric motor [100V] compatible)

●The continuous-rated, fully-enclosed fan-cooled motor is covered with integrally molded resin to improve the motor's corrosion resistance and electrical resistance.

●As a motor compatible with explosion-proof environments, we have prepared an explosion-proof motor (d2G3) specification that has passed the type test specified by the Minister of Health, Labor and Welfare.TMH-105 (100V, air motor compatible)

●A high lift (12m) and a large capacity (105ℓ/min) are possible by adopting a high-efficiency impeller.

●Surplus operation due to increased output.

●Even though it uses a large electric motor, the weight is reduced.TMH-107D (SUS) (100V, air motor, explosion-proof electric motor [100V] compatible)

●Corrosion resistant design.

● Made of SUS304, it has excellent chemical resistance. (Designed to be compatible with organic solvents)

●Non-seal structure without liquid leakage. -

TMEX models

- Pumps for Specific Applications

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Two-stage planetary gear reduction enables long-term continuous operation.

●Special rubber for high pressure resistance and Teflon lining are standard specifications, so it has excellent chemical resistance, and the horizontal repetitive motion of the rod enables the diaphragm to last forever.

●Strengthen the internal mechanism. Stepless adjustment is possible regardless of whether it is running or stopped.

●It is designed so that the intake and discharge valves are completely closed, the discharge rate is stable, and the performance curve is almost straight. -

TMTX models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Since the entire pump is covered with plastic, there is almost no rust and the appearance is not spoiled.

●Long-term continuous operation is possible due to planetary gear two-stage reduction.

●Aluminum material is used in combination to reduce weight.

● Quality has been improved by improving the ratchet mechanism. -

TMOK-S models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●The adoption of CSS (centrifugal shaft seal device) ensures that the seal is non-contact and non-sliding during operation.

There is no wear of seals due to slurry or heat generation due to dry operation.

●It is also possible to manufacture PTFE or UPE depending on the liquid used. -

TMOK-V models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Dry operation is OK due to the non-seal structure.

●Few consumable parts. -

TN models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Magnetic pump for a wide range of chemicals.

●Faithful to the basics, highly reliable and long-life design.

● Abundant series configuration from 6W to 250W.

FAQs

Provides help information on how to use each product and when you have problems.